Yes, we measure 3D geometry and GD&T parameters!

Published on September 24, 2019

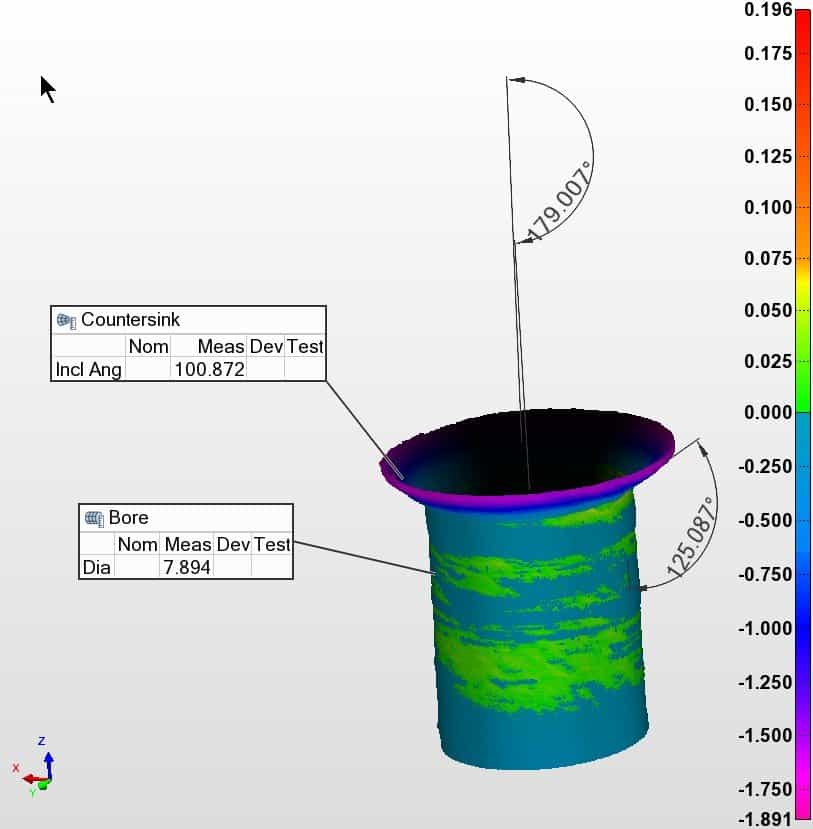

Thanks to popular demand, we now have an application page outlining range of 3D geometry measurements provided by Novacam 3D metrology systems. A few representative examples illustrate these capabilities.

Couple highlights to note:

- The precision of inside diameter (ID) measurements is typically in the 1 and 1.5 microns range (1σ), depending on the system configuration.

- 3D geometry and GD&T (geometric dimensioning and tolerancing) measurements in hard-to-reach spaces are our unique specialty, as the proportion of examples in this category indicates

- 3D geometry and GD&T measurements on both open and hard-to-reach surfaces are obtained automatically and much faster than with manual gauges or CMMs, while typically providing micron precision (again, depending on system configuration).

- We also specialize in measuring surfaces with high-aspect-ratio features and surfaces in hostile environments.

- Novacam systems are suitable for integration with robots and for inline inspection applications.

We hope that you, our reader, find the new GD&T page a useful reference.

Do you need to measure 3D geometry or GD&T parameters?