Hostile environments

Non-contact 3D metrology in hostile environments

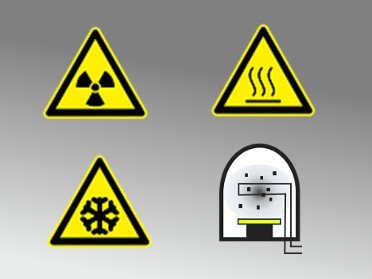

Measuring in environments involving

- Radioactivity

- Very high heat

- Extremely cold (cryogenic) temperatures, or

- Vacuum or evaporation chambers

presents challenges for both human operators and most mainstream metrology systems. But not for all.

NOVACAMTM 3D metrology systems provide non-contact metrology with sub-micron precision in hostile environments thanks to a unique combination of the underlying optical sensing technology (low-coherence interferometry) and fiber-based design.

Radioactivity, extremely heat or cold, vacuum/evaporation chambers

Advantages of measuring with fiber-based probes

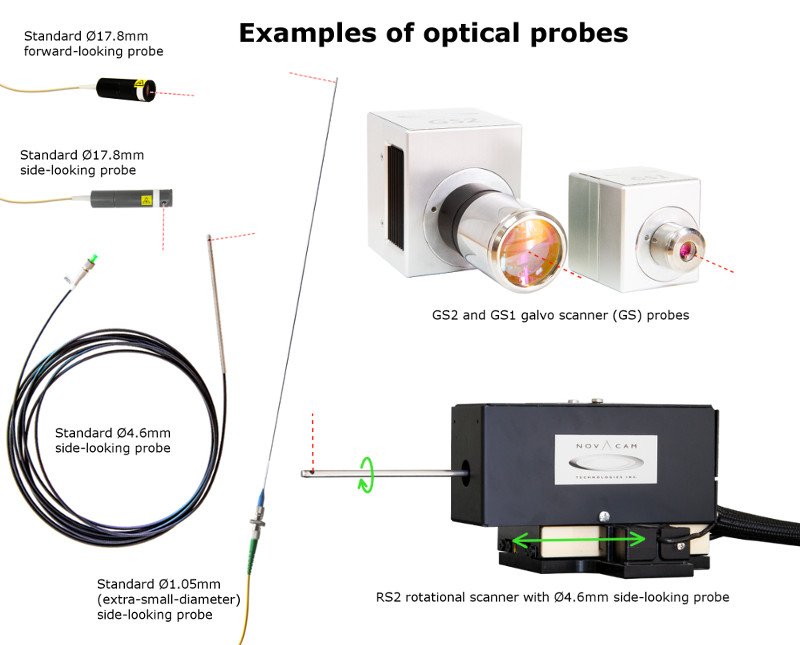

NOVACAM 3D metrology systems combine low-coherence interferometry (LCI) technology with fiber-based modular system design: A small-diameter optical probe scans the measured surface with a beam of low-coherence light. The optical signals reflected from the measured surface is captured with the probe and sent over an optical fiber (that can be several meters long) to the signal-processing detector (interferometer).

The fiber-based optical probes:

- Can be deployed several meters away from the interferometer enclosure without signal degradation

- Operate at a standoff distance of a few mm to 1,500 mm from measured surfaces

- Are able to scan through a crystal glass shield to reduce temperature and radiation

- Can be replaced at low cost if damaged or contaminated. The interferometer is typically located elsewhere, in a human-safe environment, and remains unaffected

See a more complete list of advantages of our fiber-based LCI systems.

Examples of hostile environment applications

- Radioactive environments: Novacam metrology systems measure the pitting of radioactive targets and detect both surface and sub-surface cracks in weld inspection inside reactor cooling systems. Please read Non-contact 3D Measurements for the Nuclear Industry application note [3 pages, PDF, 0.4 MB] for the types of measurements made possible with NOVACAM 3D metrology systems.

- Very hot environments: Materials that are evaporating, melting, or solidifying can all be inspected with NOVACAM rugged non-contact probes. In industries that handle extremely hot liquids, such as red-hot steel, plasma, or metals in continuous casting, the probes scan the surface in process and on a continuous basis, detecting micron-sized surface variations. Surface roughness or coating thickness characteristics are delivered at high speed to help detect defects such as minute surface cracks.

- Cryogenic environments: Our systems measure the level of liquid nitrogen in NASA’s cryogenic chambers at its Propulsion Systems Lab.

- Evaporation chambers: Our metrology systems monitor the thickness of a semi-conductor or metal coating during the deposition process. In this way, the optimal stopping time of the coating process is determined.

Related links

Download application note “Non-contact 3D Measurements for the Nuclear Industry” [3 pages, PDF, 0.4 MB] for more on 3D measurements in radioactive environments.

Contact us or request free sample analysis to see if our metrology systems are suitable for your application