Chatter

High-precision non-contact chatter measurement

What is chatter and what causes it?

Chatter is a type of defect that can seriously affect the functionality, efficacy, and longevity of machine parts. Chatter waves (lobes) are typically created by vibrations between a machining tool (such as a CNC, grinder, mill, or drill) and a part during manufacture or finishing.

Chatter is often found on the inside diameter (ID) or the outside diameter (OD) of cylindrical or conical parts.

Quick video on measuring chatter inside hollow automotive shafts

When is chatter an issue?

Chatter on parts can cause major problems during part their deployment. For example,

- Chatter on rotating parts – such as on the ID of automatic transmission clutch shafts or on the OD of threaded steering shafts – creates noise and causes premature damage to bearings, often resulting in failure and recalls

- Chatter on sealing surfaces affects the quality of the seal, causing leakage, and undesirable lowering of air or liquid pressure

How can chatter be measured?

To control chatter, manufacturers must first be able measure it. And chatter can be hard to measure, particularly in a rapid and non-contact manner, and especially when chatter is inside cylindrical or conical tubes or bores.

For many such applications, NOVACAMTM 3D metrology systems deliver fast and reliable non-contact chatter measurements on both inside diameters (IDs) and outside diameters (ODs) of cylindrical or conical components. The systems, which are based on low-coherence interferometry, offer:

- Precision better than 1 µm

- ID or OD acquisition at up to 100,000 3D points per second

- User-configurable chatter evaluation parameters

- Versatility of deployment at or near machining processes

- Real-time feedback on grinding or drilling or other machining processes: chatter can be forwarded to process control software

Measuring chatter inside CYLINDRICAL bores

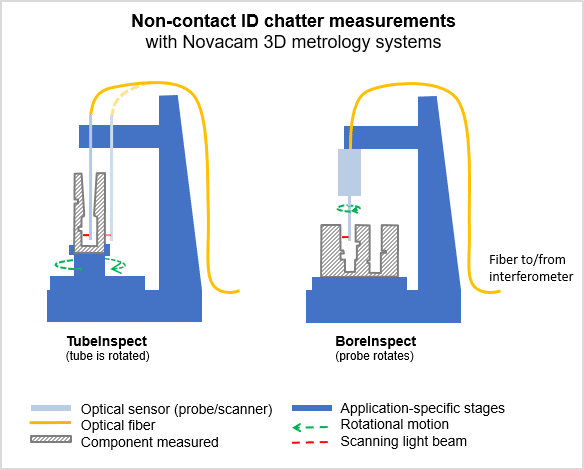

Chatter on the ID can usually be measured with one of two of Novacam non-contact 3D metrology systems: the TubeInspect or the BoreInspect (Please see their simplified schematic diagram).

Regardless of the system chosen, both TubeInspect and BoreInspect:

- Use small-diameter side-looking probes to scan the ID in a point-by-point manner in a circular or spiral pattern, as set by the operator.

- Obtain micron-precision 3D topography measurements at up to 100,000 points per second.

Once 3D point cloud of the diameter is obtained, the 3D point cloud is processed, chatter is calculated, and automatic feedback provided to the machining or sorting process and/or to the operator.

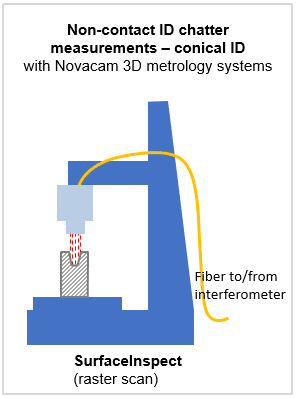

Measuring chatter inside CONICAL bores

In addition to the TUBEINSPECT and BOREINSPECT systems, chatter on conical IDs may also be measured with NOVACAM SURFACEINSPECT system (see diagram).

The SURFACEINSPECT system acquires surfaces using a galvo (raster) scanner, which can be positioned above the bore to obtain the bore ID conical surface in a very rapid, non-contact manner. The 3D point cloud obtained in this manner may be used to calculate not only chatter but also various GD&T parameters of the conical surface.

Measuring chatter on the OD

Chatter on outside diameters of cylindrical or conical parts can be measured with NOVACAM SURFACEINSPECT or TUBEINSPECT systems.

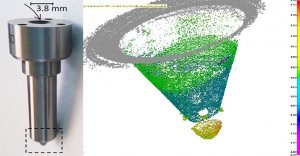

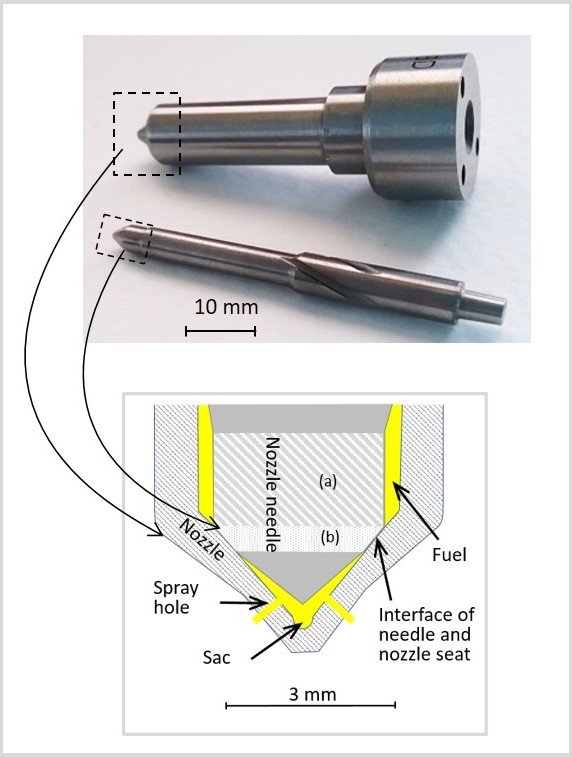

For example, the TUBEINSPECT system was used to measure the OD of the tip of a fuel injector nozzle needle (see photo and diagram).

During engine function, when the nozzle needle is pushed to its deepest position within the nozzle, its tip must form a seal with the nozzle seat in order to ensure adequate pressure on the fuel towards the nozzle spray holes. The needle geometry and surface finish are therefore crucial to the injector efficiency.

On the measured specimen, chatter marks were detected on both on the cylindrical section and on the conical section of the needle tip. The conical section is more crucial in this case.

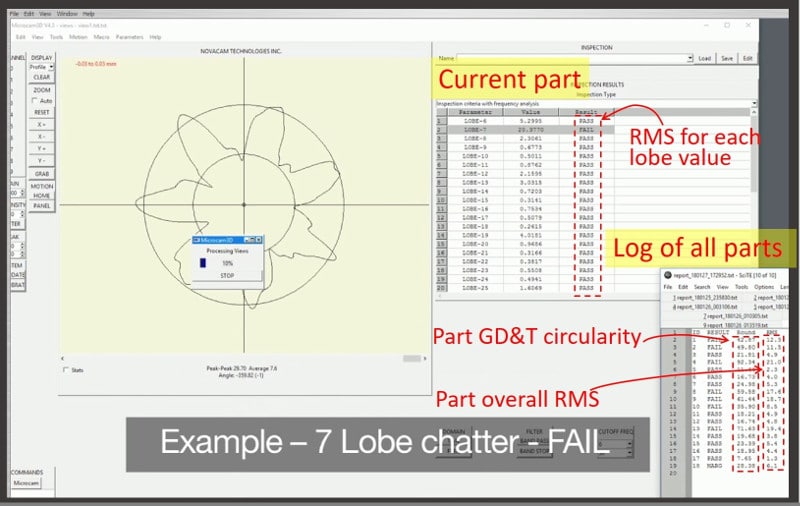

Chatter analysis software

NOVACAM Chatter Analysis Software is available to analyze the 3D surface measurement data and categorize parts as PASS or FAIL as per user criteria. The pattern of chatter is mathematically analyzed and characterized by values such as the amplitude or RMS (root mean square) value for each lobe value.

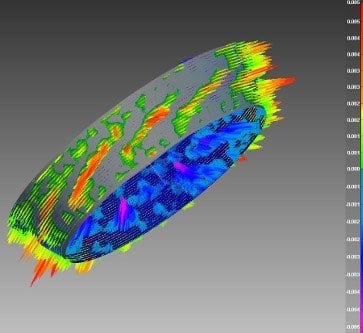

Chatter interactive viewing and analysis

Interactive viewing and analysis of the acquired 3D data is done with PC-based metrology software (e.g., PolyWorks InspectorTM). Views such as deviation maps provide key insight into machining processes that can cause chatter.

Chatter measurement solutions that are automation and shop-floor ready

With NOVACAM 3D metrology systems, automated ID or OD chatter inspection is supported by:

- System capabilities such as datum alignment, automated pass/fail reporting, and exportable reports

- Ability to interface with data loggers, enabling trend analysis with SPC software

- Fiber-based nature of Novacam sensors that can be mounted on a variety of precision stages or robot arms for integration in automated plant-floor inspection stations

- System resistance to air perturbation, ambient lighting, and to cutting of the beam

- Ability to function in harsh environments – e.g., radioactive, very hot, or cryogenic.

NOVACAM non-contact small-diameter probes that are particularly popular for ID chatter measurement come in sizes as small as 0.5 mm diameter.

As shown in the “Option1” or “Option2” photos, the part can come to the probe, or the probe can come to the part – the choice is up to each application and client.

Process improvement through chatter monitoring

Chatter induced on parts by high-volume machining tools such as centreless grinders can cause major workpiece quality issues and production losses. NOVACAM 3D metrology systems offer a reliable approach for early detection of chatter phenomenon onset through easily automated non-contact inspection of part diameters right after machining. With this approach, out-of-spec chatter is detected early and process parameters can be adjusted quickly, before product quality deteriorates.

Additional chatter measurement applications

NOVACAM 3D metrology systems also measure chatter on:

- Inside diameters (IDs) of: connecting rod bearings, piston pin bores, gudgeon and wrist pins, bushings, valve seats and actuators

- Outside diameters (ODs) of: turbine and compressor shafts, crankshaft rod journals, camshaft bearings, ball screw threads used in automotive power steering, piston pins, and more.

Related links

Watch related video:

Download application note “Measuring Chatter” [4 pages, PDF, 1 MB] for more details on this application

Explore:

Contact us or request free sample analysis to see if low-coherence interferometers are suitable for your application