High-aspect-ratio features

Non-contact measurement of high-aspect-ratio surface features

NOVACAMTM 3D metrology systems reliably characterize surfaces with high-aspect-ratio features such as steps, grooves, channels, and trenches.

The systems offer:

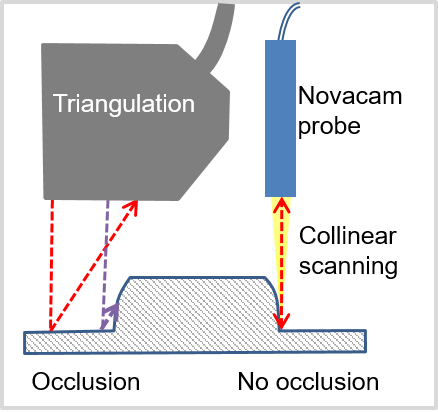

- Non-contact, collinear scanning: the emitted and received light signals travel along an identical path. No triangulation is necessary

- High speed surface acquisition: 2,100 to 100,000 3D points per second

- Sub-micron resolution

- Higher sensitivity than triangulation sensors and color confocal systems

Advantages of using a system that is modular & fiber-based

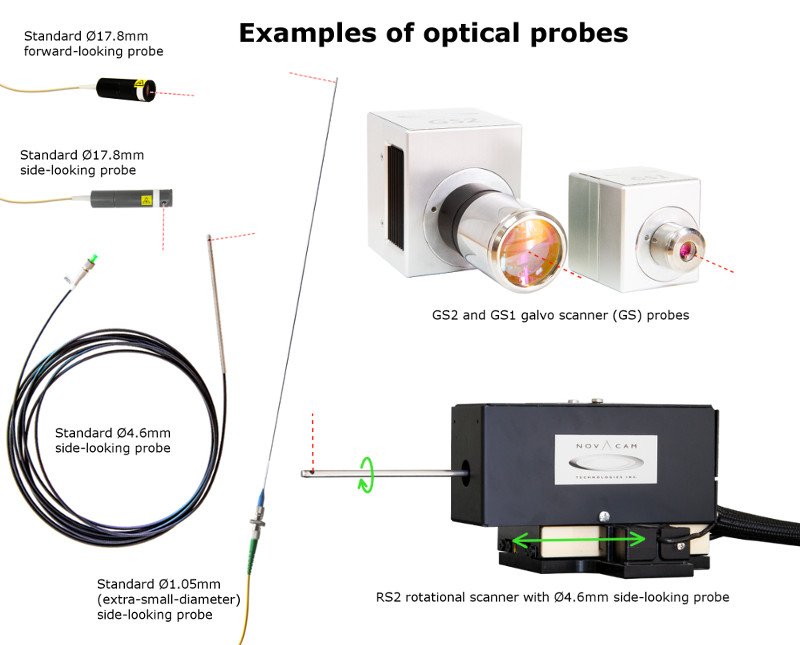

NOVACAM 3D metrology systems are modular and fiber based, meaning that the scanning optical probes are connected to the system interferometer with an optical fiber that can be several meters long. Thanks to the unique combination of Low-coherence Interferometry technology and fiber-based design, the systems offer significant advantages to our clients. These advantages include:

- Configuration versatility for both in-process and benchtop inspection

- Support for automation

- Ability to acquire long profiles

- Ability to measure inside small-diameter tubes, bores, etc. See inspection in hard-to-reach spaces

- Ability to measure surfaces with steps, grooves, channels, holes, and other high-aspect-ratio features

- Ability to scan surfaces that are reflective or nonreflective, smooth or rough, stationary or moving

- Ability to measure GD&T even in extreme temperatures or in radiation. See inspection in hostile environments.

See a more complete list of advantages of our fiber-based LCI systems.

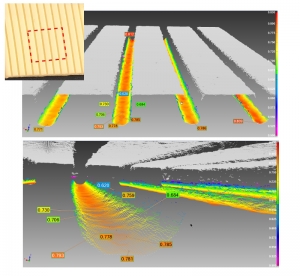

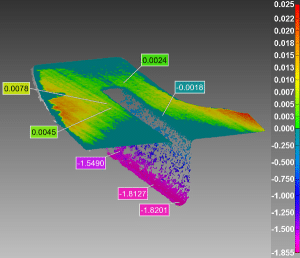

Example in semi-conductor sector

Application: measurement of CMP (chemical mechanical polishing) pads, used for wafer polishing. CMP pads are consumables made of porous polymeric material and patterned with high-aspect-ratio channels. The position, width, and depth of the grooves (channels) critically affects the CMP process performance.

NOVACAM 3D metrology systems are used to measure the geometry of CMP pad grooves during their manufacture, where the measurement process is integrated right into the CMP pad machining station. Here they help optimize the timing of drill bit replacement, lowering the cost of the process. Once deployed in the CMP process, the pads may also be measured with the same systems to measure CMP pad condition and to determine optimal timing of pad conditioning.

Metrology systems: OPTICAL 3D PROFILOMETER system (for line scanning) or SURFACEINSPECT system (for efficient area scanning)

More details: 3D metrology of CMP pads application page

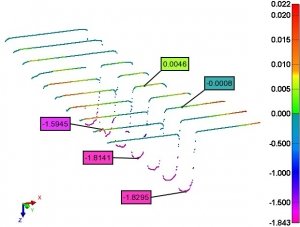

Example in aerospace sector

Application: EDM-machined blind seal slots on jet engine turbine stator blades. The slots are ~30 mm (1.2”) long, 0.4 mm (0.0157”) wide and ~1.8 mm (0.07”) deep.

Metrology system: SURFACEINSPECT system

More details: 3D metrology for EDM and laser machining application page

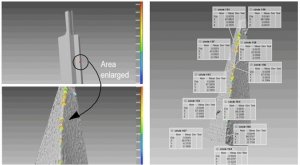

Example in metal machining / tool maintenance sector

Application: edge radius measurement

Measurement system: EDGEINSPECT system

More details: Edge radius measurement application page

Video: “Edge radius measurement” (00:01:53)

Other sectors

NOVACAM systems measure surfaces with high-aspect-ratio features in many high-precision industries:

- Aerospace: blisks (integrally bladed rotors or IBRs), turbines, cooling holes

- Automotive: fuel injector nozzles

- Dental: dental restoration inspection

- Electronics

- Fuel and solar cell production: bipolar plates

- Medical devices: tool edges, orthopedic implants with inner threads or features

- Micro-machining: edges, holes, O-ring grooves

- Tool production: cutting tool fabrication and quality control

Related links

See related applications:

Contact us or request free sample analysis to see if NOVACAM 3D metrology systems are suitable for your application