Valve inspection

Measuring Systems: NOVACAMTM OPTICAL 3D PROFILOMETERTM system, BOREINSPECTTM system, or TUBEINSPECTTM system

Keywords: non-contact, valve inspection, inside diameter, ID

Trend towards non-contact in valve inspection

Conventional contact methods of valve inspection are making way for newer, non-contact methods. While international standards for surface roughness are still set as per observations by contact profilometers, the convenience and speed associated with state-of-the-art non-contact technologies are obvious reasons why more and more experts are opting for non-contact.

Unique advantages with NOVACAMTM 3D metrology systems

Inspecting valves with NOVACAM 3D metrology systems provides clients with:

- Micron-precision 3D measurements and exceptional measurement repeatability of up to 0.0625 µm on roughness and 0.5 µm for diameter measurements

- Ability to measure–with the same instrument–valve dimensions (GD&T parameters), roughness, and/or defects

- High speed surface acquisition: up to 100,000 3D points per second

- Ability to acquire long profiles

- Surface measurement in hard-to-reach spaces such as small-diameter valves

- Ability to measure high-aspect-ratio features inside valves, such as O-ring grooves, channels, threads, cross-holes, splines, etc.

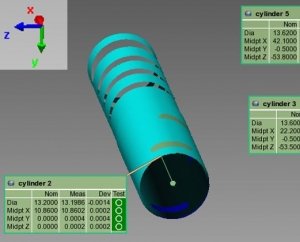

Watch a demo of a fully-automated digital inspection of valve body bores with NOVACAMTM BOREINSPECTTM system. Here, the system rotational scanner (RS2) advances a small-diameter optical probe inside bores to measure their inside diameters (IDs) down to the micron.

Facilitated automation

NOVACAM 3D metrology systems are based on low-coherence interferometry technology. They are also modular and fiber-based, meaning that their small-sized probes (or rotational scanners) are connected to the signal-processing interferometric detector with an optical fiber. As such,

- The measuring probe (or rotational scanner) is easily integrated in a variety of valve inspection stations in automated or semi-automated systems on the plant floor, and,

- If the valve is located in a hostile environment,(i.e. radioactive, very hot or very cold), the measurements can still be made.

See a more complete list of advantages of NOVACAM fiber-based LCI systems.

Off-the-shelf or customized valve inspection solutions

NOVACAM BOREINSPECT and TUBEINSPECT systems offer off-the-shelf inspection solutions to most valve inspection needs:

- The BOREINSPECT system uses a spinning optical scanning probe (called RS2) to measure the insides of stationery valves

- The TUBEINSPECT system uses a small-diameter side-looking probe to measure interiors of valves mounted on a rotational stage.

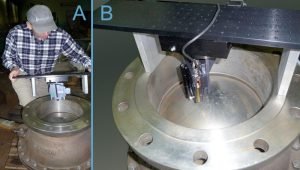

Customized inspection stations are also available. Pictured is a custom inspection station with NOVACAM OPTICAL 3D PROFILOMETER that provides a surface roughness check of an extra-large valve.

Related links

Watch related videos:

See related applications:

See related products:

Contact us or request free sample analysis to see if our 3D metrology systems are suitable for your valve inspection application