News & Events

This page is Novacam’s channel for company news, upcoming event announcements, and 3D metrology insights relevant to professionals in charge of high-precision measurements across industries.

Click here to subscribe to Novacam’s newsletter that comes out 3 to 4 times a year. Older newsletter issues are available here.

Report from Automate 2019 in Chicago

/by radkaBrief report, including a video of our BoreInspect in action at our booth.

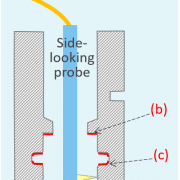

How to measure O-ring grooves, blind-hole corners, and undercuts

/1 Comment/by radkaNovacam provides a custom solution for measuring extra hard-to-reach spaces inside tubes and bores. These include blind hole corners, undercuts, o-ring grooves (walls and inside corner radii) and more.

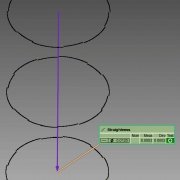

How to measure axial straightness of bore, tube, or barrel IDs

/by radkaMany tubes, bores and barrels in high-precision industries must meet strict criteria for straightness. Read about Novacam’s solution for such applications.

Novacam systems in 2 Japan trade shows this year

/by radkaCome see Novacam systems in 2 Japan trade shows this year: at OPIE 2019 (April 24-26) in Yokohama and at MECT 2019 (October 23-26) in Nagoya .

No more rubber replicas – automated measurement inside tight spaces

/2 Comments/by radkaUsing rubber or silicone replication for high-resolution measurement is time-consuming, labour intensive, and practical only for inspecting small areas inside hard-to-reach spaces. Novacam BoreInspect and TubeInspect offer a new approach – direct, non-contact 3D measurements right inside such spaces.

Visit Novacam at Automate 2019 in Chicago

/by radkaNovacam booth #8558 in Chicago’s Automate 2019 Show (April 8-11) will feature our 3D metrology solutions in action.

ID and OD chatter measurement: high-precision, non-contact and automated

/by radkaChatter is a type of defect that can seriously affect the functionality, efficacy, and longevity of machine parts. Our new application page explains how chatter can be measured automatically on either inside and outside diameters of parts – with high precision and in a non-contact manner.