PRODUCTS

Industrial 3D metrology systems

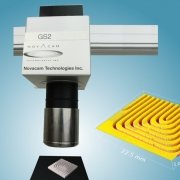

All of NOVACAMTM 3D metrology systems are non-contact, fiber-based, and suitable to industrial environments as well as R&D. They are able to acquire dimensions, thickness, roughness, and defects. They combine micron-resolution with hard-to-beat versatility.

3D Metrology systems

OPTICAL 3D PROFILOMETER systemAcquires non-contact micron-precision 3D measurements: dimensions, roughness, defects, vibrations, and/or thickness measurements. Even in hard-to-reach spaces-bores, tubes, etc. Option to acquire long profiles to support continuous in-line inspection.

OPTICAL 3D PROFILOMETER systemAcquires non-contact micron-precision 3D measurements: dimensions, roughness, defects, vibrations, and/or thickness measurements. Even in hard-to-reach spaces-bores, tubes, etc. Option to acquire long profiles to support continuous in-line inspection.

TUBEINSPECT systemObtains non-contact micron-precision 3D measurements of tube ID and OD surfaces and other hard-to-reach spaces (barrels, shafts, etc.). Ideal for tubes that can be spun on a rotational stage.

TUBEINSPECT systemObtains non-contact micron-precision 3D measurements of tube ID and OD surfaces and other hard-to-reach spaces (barrels, shafts, etc.). Ideal for tubes that can be spun on a rotational stage.

BOREINSPECT systemObtains non-contact micron-precision 3D measurements of bore holes and other hard-to reach spaces. The system’s rotational probe measures interiors of manifolds, valves, turbine blades, medical equipment, dies, and more.

BOREINSPECT systemObtains non-contact micron-precision 3D measurements of bore holes and other hard-to reach spaces. The system’s rotational probe measures interiors of manifolds, valves, turbine blades, medical equipment, dies, and more.

SURFACEINSPECT systemObtains non-contact micron-precision 3D measurements of object geometry, GD&T parameters, roughness, thickness, or defects.

SURFACEINSPECT systemObtains non-contact micron-precision 3D measurements of object geometry, GD&T parameters, roughness, thickness, or defects.

EDGEINSPECT systemObtains non-contact micron-precision 3D measurements of edge breaks/edge radiuses: 3D geometry, GD&T parameters, roughness, thickness, and defects.

EDGEINSPECT systemObtains non-contact micron-precision 3D measurements of edge breaks/edge radiuses: 3D geometry, GD&T parameters, roughness, thickness, and defects.

RIVETINSPECT systemAutomatically measures rivet hole IDs, rivet countersinks, as well as rivet head flushness upon installation. Combines functionality of BoreInspect and SurfaceInspect. More details here.

RIVETINSPECT systemAutomatically measures rivet hole IDs, rivet countersinks, as well as rivet head flushness upon installation. Combines functionality of BoreInspect and SurfaceInspect. More details here.