EDGEINSPECTTM system

for high-precision 3D metrology of edge breaks/edge radiuses

NOVACAMTM EDGEINSPECTTM system is a modular, non-contact 3D metrology system that:

- Measures, down to the micron, any type of edge: cutting edges, inside or outside edges, edges on round holes, straight edges, etc.

- Enables user-defined specifications: for geometric dimensioning and testing (GD&T), edge break requirements, angle measurements, roughness, etc.

- Enables fully configurable automated inspection

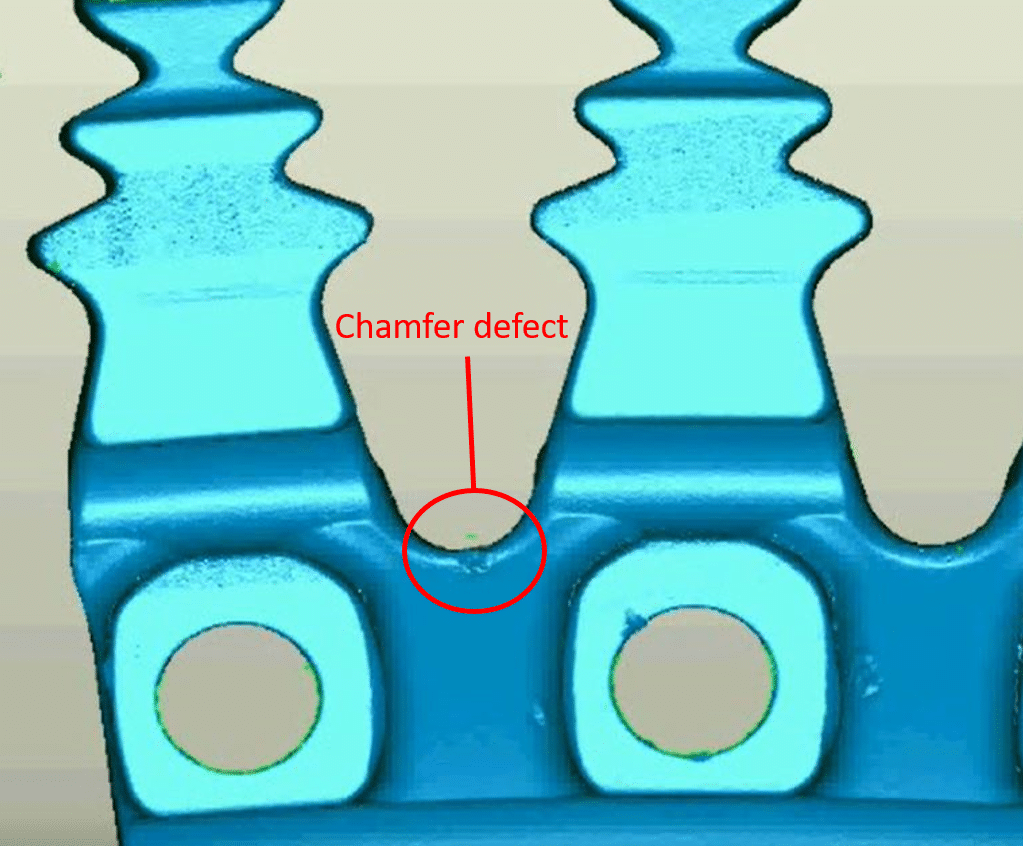

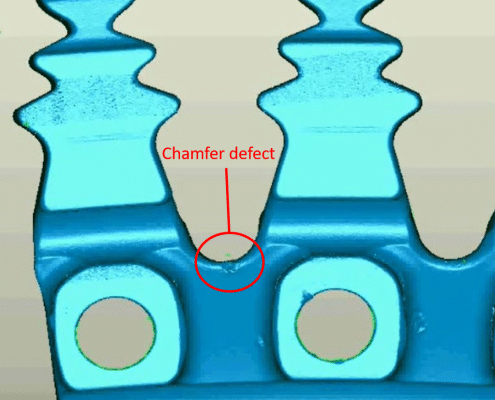

- Detects micron-size surface defects: such as burrs, scratches, porosities, etc.

- Can measure thickness of semi-transparent coatings.

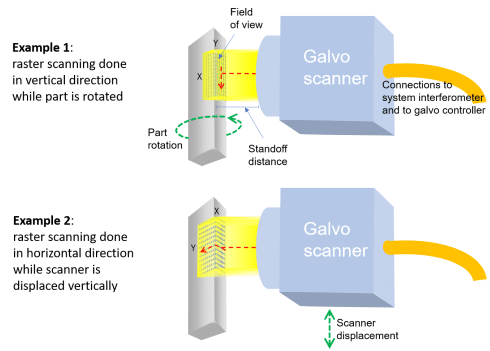

The galvo scanning probe of the EDGEINSPECT system acquires surfaces in a raster fashion. Standard fields of view (FOV) go up to 85 x 85 mm. Larger samples are acquired by displacing the galvo scanner and/or samples using linear stages.

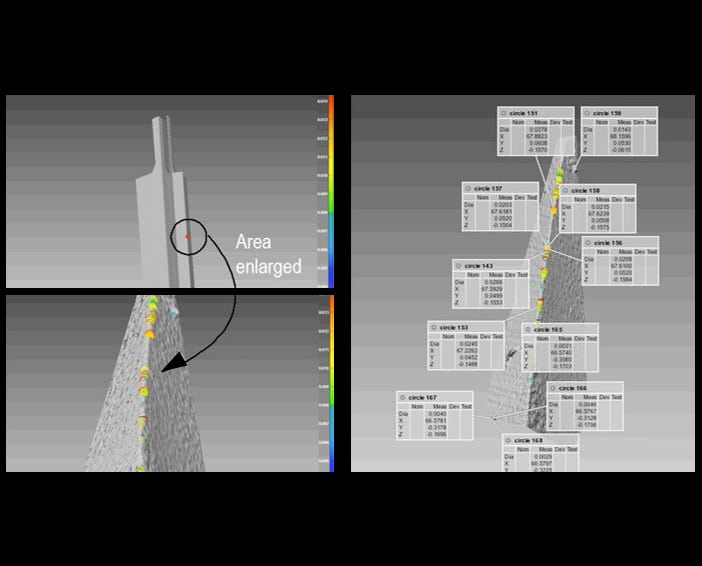

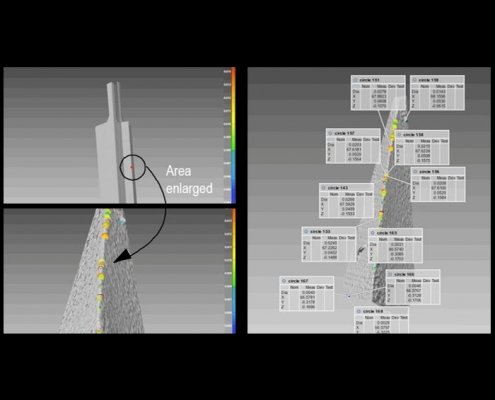

Edge radius measurement

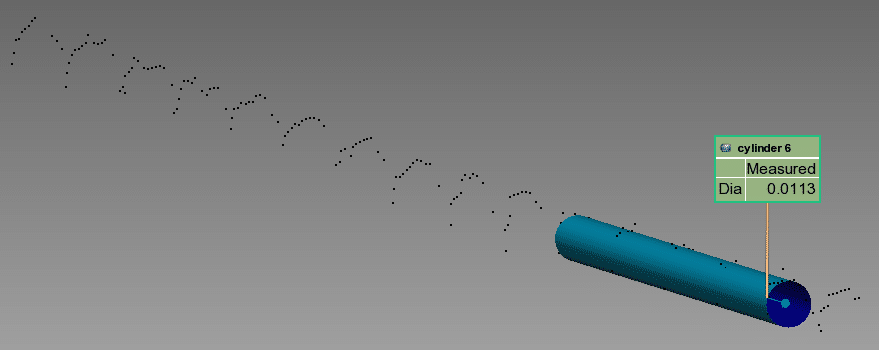

In this video, a drill bit is rotated on a chuck base while the galvo scanner probe of the EDGEINSPECT system inspects the tool from top to bottom following a user-defined scanning sequence.

- Chapters

- descriptions off, selected

- captions settings, opens captions settings dialog

- captions off, selected

This is a modal window.

Beginning of dialog window. Escape will cancel and close the window.

End of dialog window.

Overview of features and benefits

Measurements

- Optical, non-contact, non-destructive

- High speed: Up to 100,000 3D point measurements per second

- 2D and 3D edge geometry of cutting edges, leading and trailing edges, edge radiuses, chamfers, bevels, notches, fillets, thread mills, etc.

- High-aspect-ratio features: undercuts, threads, splines and gears

- Micron-precision axial resolution and excellent sensitivity and measurement repeatability

Imaging options

- Line profiles

- 3D images of internal and external surfaces

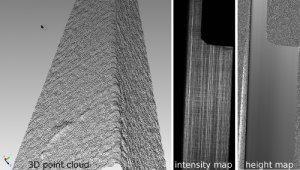

- Height and intensity images of “unfolded” surfaces

- Cross-sections of semi-transparent materials

- Deviation maps

Benefits

- Easily integrated in lab, shop, or fully-automated industrial inspection setups

- Reduces inspection cycle time: the non-contact optical scanner (or probe, depending on the setup) obtains up to 100,000 measurements per second. Each measurement represents a 3D topographic point.

- Flexible options for evaluating inspected parts: measured features can be compared to CAD drawings or to a user-defined set of locations, nominals, and tolerances

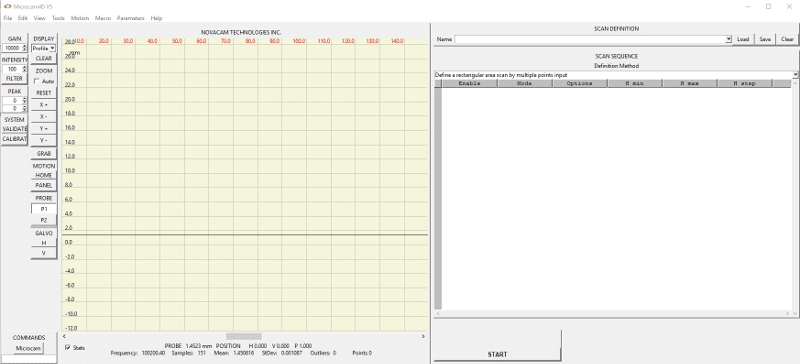

- Simple scan definition and execution: The scanning sequence is defined once by teaching the system with a joystick. The scanning sequence can later be executed with the push of a button.

- Time-saving automated reporting:Following a scan, go-no-go reports can be produced and results logged in a manner compatible with industry-standard mechanisms.

- Adaptable to harsh environments

- No consumables are needed: Optical probes do not come in contact with the measured samples, and therefore do not wear out like contact probes. Accidental damage is rare−probes are designed to be rugged.

Metrology Applications

3D metrology and imaging of edges for industry and R&D

- Quality control

- Automated 3D production inspection, geometric dimensioning and tolerancing (GD&T)

- Statistical process control (SPC)

- Research and development (R&D) inspection

- Reverse engineering and part-to-CAD

- Maintenance, repair and operations (MRO)

- Profilometry in harsh environments

Typical measurements on edges

- Full geometry, diameter, circularity, cylindricity, taper, runout, etc.

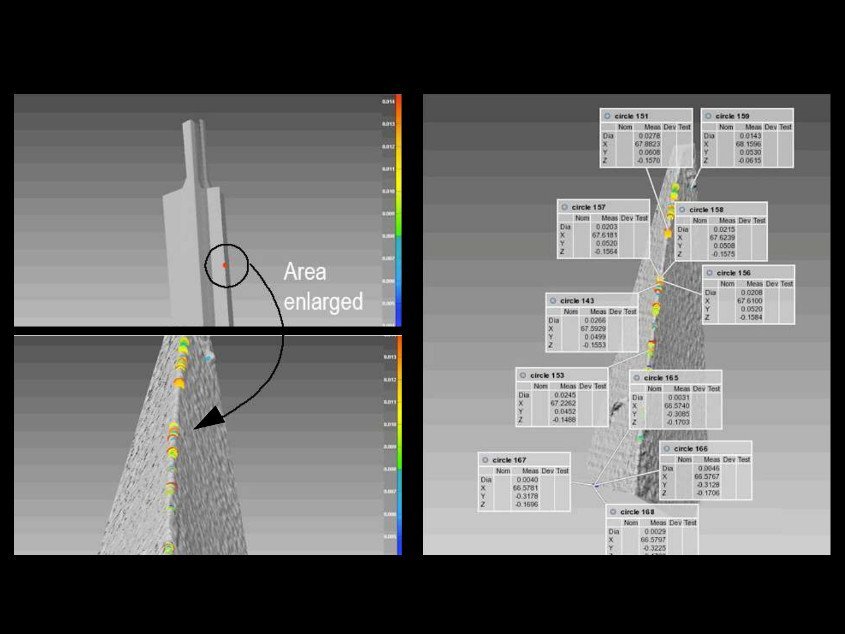

- Deviation from CAD model

- High-aspect-ratio features: teeth, undercuts, steps, grooves, threads, channels, sharp edges, cross-holes

- Volume loss: surface wear or other damage

- Defects: corrosion, pitting, cracking, denting, scratching, porosity

- Surface roughness: linear or area roughness

- Thickness of semi-transparent coating on edge surfaces: single-layer or multilayer films

Examples of edge inspection applications

Measurement, visualization, and GD&T inspection of edges on:

- Parts made by machining (drilling, milling, grinding, honing, etc.), casting, injection molding, 3D printing, additive manufacturing

- Cutting tools before and after treatments

- Cutting tool maintenance, sharp edge measurement, burr detection

- Scalpels, syringes, needles, razor blades, spindles

- Automotive industry parts

- Aerospace jet engine turbine blades with cooling holes

- Hydraulic systems, bearings, tubes

- Sheet metal parts

- Chamfered edges, bevel edges, filleted edges, miter edges

- Wafer edges

System Software

The EDGEINSPECT system comes with NOVACAM high-performance data acquisition software, which is PC Windows®-based and user-friendly for scan programming.

The system simultaneously generates 3 data sets from the same scan: 3D point cloud, light intensity image, and height image. The height and light intensity images facilitate defect detection. STL file format is also available.

For full GD&T analysis of measured parts, a turnkey solution is available with InnovMetric metrology software PolyWorks InspectorTM that may be purchased with the EDGEINSPECT system.

- Go-no-go reporting is easily programmed and automated, providing measurements such as edge radius, angle, angularity, etc.

- Users benefit from capabilities such as a quick visual comparison (deviation map) of the acquired part measurements to pre-specified tolerances or to the CAD of the part.

Visualizing the scan data may be accomplished by importing the data into various third party visualization and numerical analysis software, such as PolyWorks Inspector, Geomagic, ImageJ, SolidWorks, Octave, MatLab, Mathematica, IDL, or IGOR Pro.

Deriving application-specific measurements from the 3D point cloud is available through a selection of in-house and third party software. Novacam supports the following options:

| Novacam in-house software | 3rd party software, such as | |

|---|---|---|

| Dimensional measurements (GD&T parameters) | PolyWorks Inspector (turnkey solution) Geomagic |

|

| Roughness and surface analysis | TrueSurf, MountainsMap | |

| Thickness | ||

| Chatter (vibration) | ||

| Volume loss | ||

| Defects | Custom-developed* | |

| * Novacam offers the option of custom data processing, reporting, and defect detection programs that can be written based on client requirements. | ||

An application programming interface (API) is available for system integrators and OEMs to accommodate a wide variety of online and offline applications. Exported results may be integrated with data loggers and SPC software.

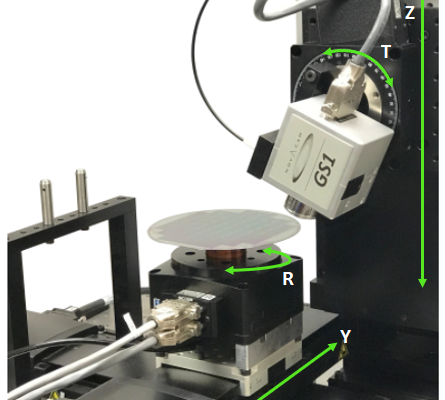

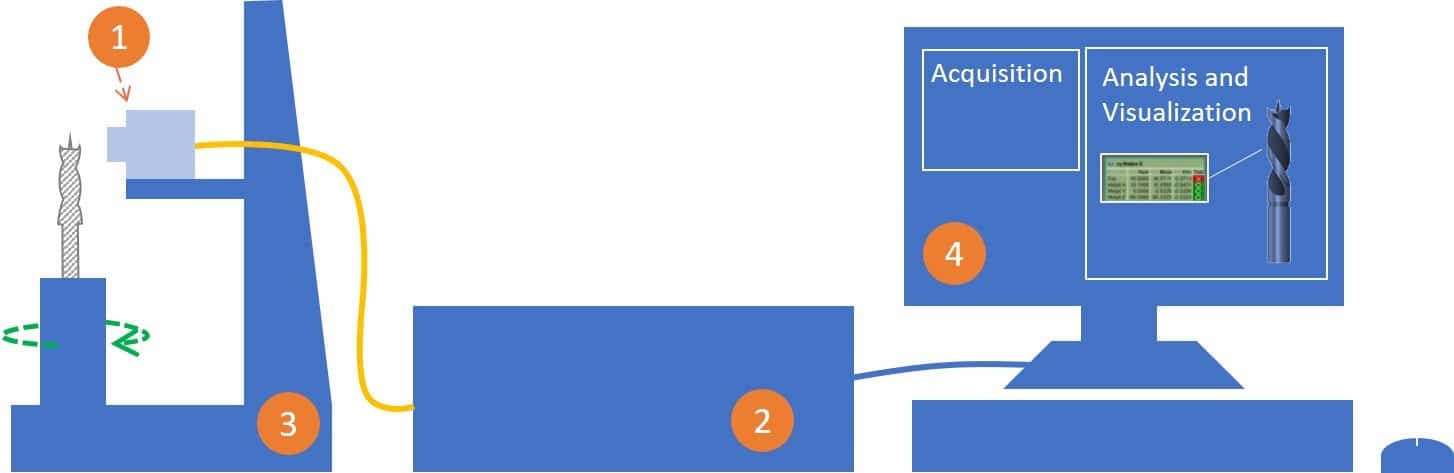

NOVACAMTM EDGEINSPECTTM system is a fiber-based modular system that comprises 1) Galvo (raster) scanner, 2) MICROCAM interferometer, 3) Inspection station, 4) PC, 5) Galvo controller and motion controller(s) (not shown), and 6) Multiplexing hardware (optional, not shown).

Galvo scanner

Microcam interferometer

Inspection station

PC, monitor and joystick

The inspection capabilities of the EDGEINSPECT system are determined jointly by its components:

1) Galvo scanner (GS)

The GS acquires 3D surfaces or material thickness in an efficient raster pattern. Its housing is robust and shop-floor ready.

Standard GS characteristics*

| Field of view (mm) | Standoff distance (mm) |

|---|---|

| 4.7 x 4.7 | 7.5 |

| 9.4 x 9.4 | 25.1 |

| 14.1 x 14.1 | 42.3 |

| 18.8 x 18.8 | 64 |

| 28.9 x 28.9 | 93.8 |

| 30 x 30 | 87.5 |

| 43 x 43 | 137 |

| 54 x 54 | 126 |

| 84 x 84 | 215.4 |

| *Only standard galvo scanner characteristics are listed in this table. Non-standard specifications are custom-built upon request. | |

2) MICROCAM interferometer

The MICROCAM interferometer provides the light source to the galvo scanner and processes the optical signal received from the scanner. The GS and the interferometer are connected with an optical fiber.

MICROCAM interferometer models

| MICROCAM-3D | MICROCAM-4D | |||

|---|---|---|---|---|

| General characteristics | ||||

| Technology | low-coherence interferometry | |||

| Light wavelength | 1310 nm, infrared | |||

| Size of interferometer enclosure box (depth x width x height) | 4U rackable enclosure 445 x 445 x 178 mm |

|||

| Non-contact measurements | ||||

| Depth of field | depends on the characteristics of the selected scanner (see table above) | |||

| Scanning depth range options* | 3.5 mm | 7 mm | 5 mm | |

| Acquisition (A-scan) rate | 2.10 kHz | 1.05 kHz | 100 kHz | |

| Axial (Z-axis) resolution | < 0.5 µm | |||

| Light spot size (Lateral [XY-axis] resolution) | 4.1 - 146 µm, depends on selected scanner characteristics. | |||

| Standoff distance | 1 - 100 mm for standard probes up to 1 m for non-standard probes |

|||

| Repeatability | < 1 µm | |||

| Thickness measurements | ||||

| Thickness measurement range (in Air, IR = 1.0) | 10 µm - 3.5 mm | 10 µm - 7 mm | 20 µm - 5 mm | |

| Typical materials for thickness measurements | glass, polymers, multi-layer films, coatings, plastics, silicone, liquids, specular or non-specular | |||

| Sample reflectivity | 0.1 - 100% | |||

| *To further increase maximum scanning depth, a mechanical displacement axis is available. | ||||

3) Inspection station

Measurement may be carried out in 2 modes:

- Scanning in X direction only, where the scanned surface is moving relative to the lens in the Y direction

- Scanning in both X and Y direction to obtain an area at a time, with multiple scans stitched together if required.

For automated inline industrial inspection, NOVACAM galvo scanners may be integrated with precision stages or robots (as robot end-effectors) to support high-volume continuous flow manufacturing. They can also be integrated with third-party CMMs (coordinate-measuring machines) and CNC (computer numerical control) machines.

4) PC, monitor and joystick

The EDGEINSPECT system comes with a PC (with NOVACAM acquisition software), monitor, mouse, and joystick.

5) Galvo and motion controller(s)

The galvo controller and motion controller(s) are included. The galvo controller controls the motion of the light beam within the raster pattern. Depending on the number of additional motion axis required, the motion controllers are housed in a 2U, 3U, or 4U rackable enclosure.

6) Hardware for multiplexing support (optional)

With optional optical switches, more than one galvo scanner (possibly in combination with one or more optical probes) may be multiplexed to a single MICROCAM interferometer. Multiplexed galvo scanners and probes may be used one at a time. This option brings additional return on investment (ROI) to many installations.

Standard system configuration

A standard configuration of the EdgeInspect includes:

- Galvo scanner with a 5x5mm field of view

- Microcam-3D profilometer

- 2-axis inspection station and 2-axis motion controller

- 3-jaw chuck

- PC with Novacam acquisition software

- 1 year warranty

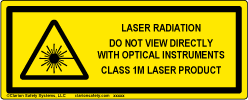

Instrument safety

- Microcam systems feature an in-probe red laser pointer (650 nm wavelength) for alignment purposes.

- Microcam systems are Class 1M Laser products, with < 20 mW of infrared and < 5 mW of in-probe laser pointer.

EdgeInspect in the news

The EdgeInspect system was recently featured in Cutting Tool Engineering magazine.

Frequently asked questions

How long does it take to scan an edge with the EDGEINSPECT system?

- Scan time of an edge depends on the area size and aspects you need to measure. The EDGEINSPECT system acquires up to 100,000 measurements per second, which represents roughly 1 million 3D topography points in 10 seconds. The user selects the lateral sampling distance in longitudinal and circumferential directions and the size of the area to be scanned, which together determine the number of points that will be acquired and the time that the scan will take.

- In general, dimensional measurements (for GD&T) require the least amount of points and can be achieved the fastest. Roughness callouts may take 3 to 4 seconds each. Defect detection requires the most amount of points, of course depending on the size of defect you are looking for.

- For help with estimating the time required to scan your part, please contact us.

Can the EDGEINSPECT system be used to measure the thickness of a coating on edges?

- Yes, if the coating is semi-transparent to infrared light and has optical thickness of 20 µm or higher (optical thickness = physical thickness * index of refraction).

How about inside corners – i.e. does the EDGEINSPECT system measure inside edges in concave forms?

- The EDGEINSPECT system can measure both inside corner edges as well as outside edges. In both cases, it can delivers high-precision diameter, contour, profile, and coating (or material) thickness measurements.

Can the EDGEINSPECT system measure very sharp edges?

- Yes, depending on the geometry of the features to be scanned. Various radius of curvatures as small as 6 µm have been scanned.

Is the system easy to use?

- The scanning sequence (recipe) can be programmed with a joystick and can be recalled at later times with the push of a button.

Is the system able to work right on the production floor?

- The system is ideally suited for both lab and shop floor inspection. Inline and robot setups are also supported. The EDGEINSPECT system can even be used to provide metrology in hostile environments such as extremely hot, cryogenic, or radioactive.

Can SurfaceInspect give us automated measurements and reports?

- Yes.

Related links

See related applications:

Contact us or request free sample analysis to see if the EDGEINSPECT system is suitable for your application