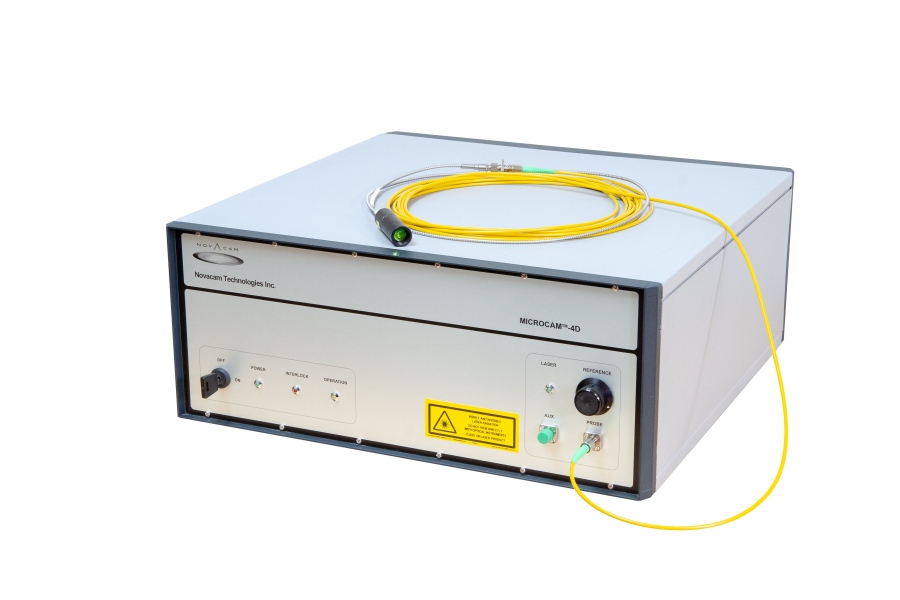

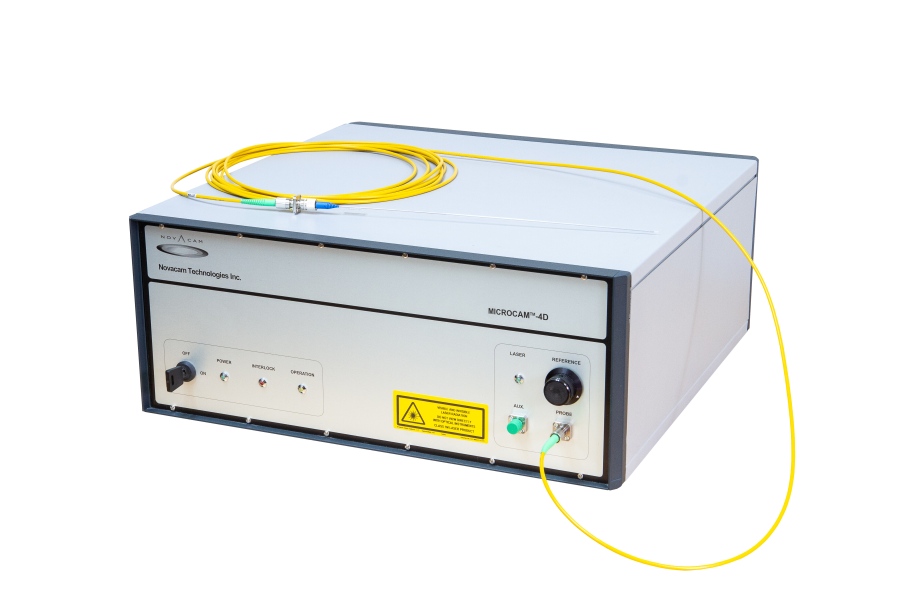

MICROCAMTM-3D/4D interferometer

for high-precision non-contact surface & thickness measurements

As a core component of any NOVACAMTM 3D metrology system, the MICROCAMTM-3D/4D interferometer provides light source to optical scanning probes and carries out the optical and electronic processing of measurements.

Novacam interferometers MICROCAM-3D and MICROCAM-4D offer:

- Micron-precision 3D measurements – roughness, geometry (GD&T parameters), thickness, vibration, defects

- Fast acquisition rate of up to 100 kHz, i.e., 100,000 3D point measurements per second

- Measurements not affected by ambient lighting, air perturbation, or cutting of the beam

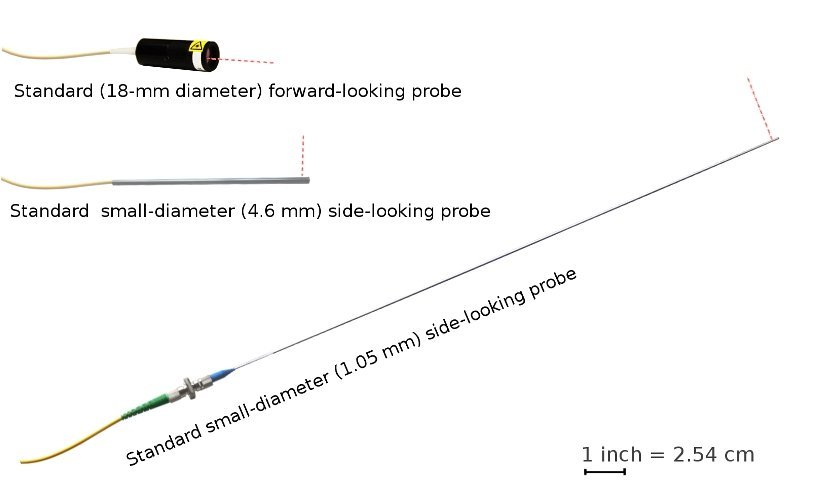

- Modularity and versatility of deployment, with fiber based optical probes that may be integrated on motion stages, robots, gantrys, CMMs, and CNCs.

- Many additional advantages offered by the underlying technology, low-coherence interferometry.

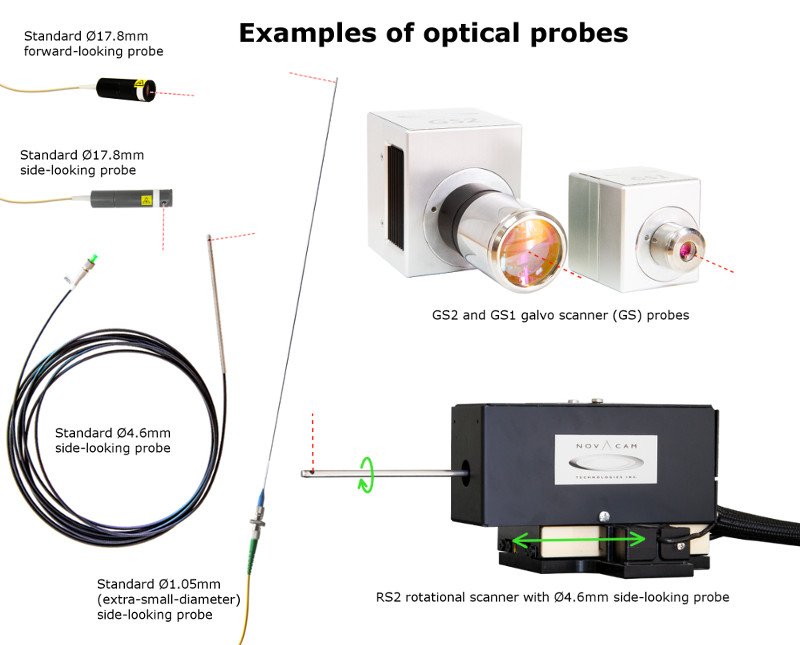

A selection of NOVACAM fiber-based optical probes is available to provide non-contact surface and cross-sectional measurement in a wide range of industrial inspection applications.

Overview of features and benefits

Measurements

- Optical, non-contact, non-destructive

- High speed: up to 100,000 3D point measurements per second

- Micron resolution, excellent S/N ratio

- 2D and 3D surface and subsurface characterization

- Roughness, geometry, thickness, vibration

- Long stroke profilometry

Imaging

- Surface profiles

- Cross-sections of transparent or semi-transparent material

- Volumetric images

Fiber-based probes

- Inspect even inside bores, tubes, and crevices

- Are non-contact and therefore not a consumable

- Are easily installed wherever required in the process—on a CNC, robot head, or any combination of precision stages

- Provide versatility for high-speed online inspection

Benefits

- Wide range of materials: metal, plastics, polymers, glass, metal coatings, silicone, adhesives; reflective, transparent, semi-transparent, specular, nonspecular

- Wide range of objects and surfaces: objects can be small (several microns wide) to large (no upper limit), stationary or moving, solid or liquid, and include interiors of bores and tubes, exteriors of cylinders, concave or convex spherical shapes, extremely hot or cold, or radioactive

- Measurements not affected by ambient lighting, air perturbation, or cutting of the beam: systems suitable for industrial-floor deployment as well as lab environment

- Versatility of setup: Non-contact fiber-based probes work up to 1 m away from surface

- The same profilometer is capable of measuring roughness, geometry, and defects. This allows many of our clients to use the system for a variety of related inspection tasks.

- Small-diameter probes reach in to measure insides of bores and small-diameter tubes

- High-aspect-ratio surface features can be acquired: channels, grooves, steps, sharp edges, and more

- Continuous, long profile scanning: no area stitching required

- Easy integration of fiber probes in labs and in process: on XY tables, on multi-axes scanning mechanisms, inside machining centers, above moving webs, etc.

- Rugged probes: inspection possible in hostile environments where humans cannot work

- Option of multiplexing probes with single interferometer for additional ROI

- USB connection for data transfer from interferometer to PC or laptop

See related applications:

Contact us to discuss your application needs