Custom solutions

Services

Novacam develops custom interferometric solutions to address particular inspection and imaging needs of specialized applications and OEM markets. NOVACAMTM product line of standard systems and modular interferometer components offer a superior and cost-effective platform for developing high-performance systems and assemblies. We will collaborate with your application experts to devise the optimal combination of inteferometric (OCT) hardware, non-contact fiber-based sensor probes, and system software.

As needed, Novacam engineers:

- develop customized optical probes and inspection stations

- develop inline probe fixtures for production environments

- adapt NOVACAM standard interferometer component modules to suit your application

- help integrate NOVACAM systems or components with third-party tools

- write customized software

Examples

Novacam has a long history of success in developing custom solutions. Here are some examples:

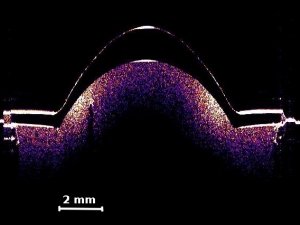

1) Intra-ocular lens inspection

Novacam solution:

- Customized application software determines lens curvature, thickness and smoothness

- Flexible user interface permits operator control of data gathering at preset coordinates

Features and benefits:

- Fully automated lens characterization

- Micron precision measurements at operator-set points

- Lens inspection process sped up more than 10 x

- Defect detection rate increased to 100%

- Cost savings by early detection of defects

- Simplified job training

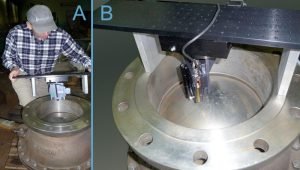

2) Inner diameter inspection of cylinders (applicable to tubes, bores)

Novacam solution:

- A customized inspection station helps acquire the inner surface of a cylinder in one continuous motion

- A single probe is rotated to acquire micron-precision dimensional information of cylinder interior

- Simultaneous dimensional and surface roughness check

Features and benefits

- Inspection time cut in half: dimensional and surface measurements performed in a single step rather than traditionally with two different instruments

- Small lightweight probes easy to integrate into production processes

- Non-contact technology improves system reliability and availability

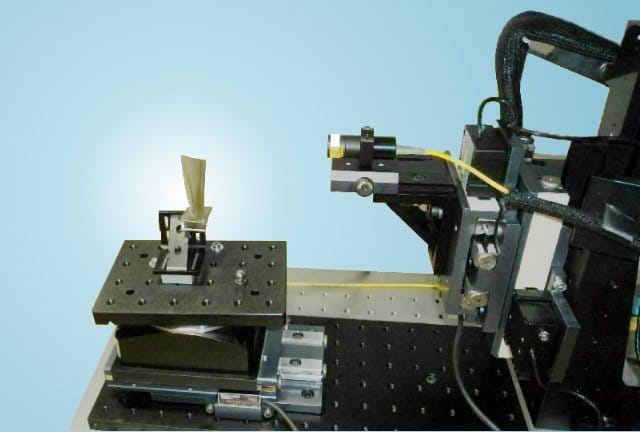

3) Blade airfoil 3D inspection

4-axis inspection station for 3D characterization of machined components

Novacam solution:

- Customized 4-axis inspection station with rotating platform scans blade from all directions

- Simultaneous acquisition of:

- blade dimensions

- surface roughness

- defects

- inside diameters of miniature cooling air holes created by electrical discharge machining (EDM)

Features and benefits:

- User-friendly interface for controlling and automating movement sequences

- Inspection and reporting fully automated

- Measurement rate 100 x faster than modern CMM rates

- OPTICAL 3D PROFILOMETER system scans at its maximum speed without any loss of precision. In contrast, CMMs must decrease scan rates for the highest precision.

- In-process integration possible with TCP/IP-based protocols

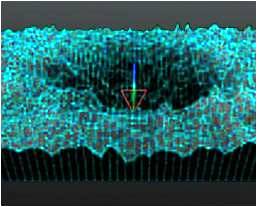

4) Integration with LIBS and other spectroscopy equipment

Non-transparent material thickness measurement using Novacam Optical 3D profilometer integrated with client’s own Laser-Induced Breakdown Spectroscopy (LIBS) system.

Novacam solution:

- A LIBS device focuses and pulses a laser beam on a sample, vaporizing some material, and performs spectral analysis on the resulting plasma. Novacam’s 3D metrology systems, based on low-coherence interferometry, measure the depth to which material has been removed. Since light sources used by both technologies are in the same range, customized devices have been constructed using a common light path configuration.

- Novacam offers assistance with integrating our technology with customers’ own LIBS system.

Features and benefits:

- Inspection and reporting fully automated

- Small lightweight probes easy to integrate into LIBS and other spectroscopy processes

- In-process integration possible with TCP/IP-based protocols

Related links

Contact us to discuss your application needs

Request free sample analysis to see if our technology is suitable for your application